Fresh out of the mould |

Look; no stitched seam! |

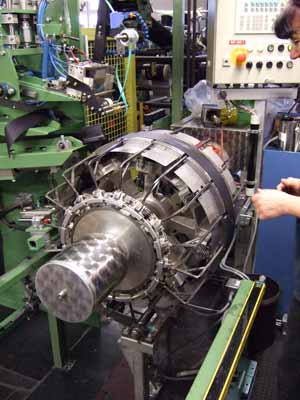

The carcass folding machine |

Operator places inner tube in pocket |

Both sides have been folded over |

Tub is vulcanised complete |

Continental GP4000 Tubular £42.95 21mm

Following Continental’s introduction of the Sprinter Gatorskin, an all-purpose tubular tyre based on the successful Gatorskin clincher, we now have the Grand Prix 4000 tubular featuring Black Chili compound. Continental uses tyre technology tried and tested with the Grand Prix 4000S clincher in this tub, which is made using a seamless construction (see below). Continental are famous for their tubs, especially the Competition, which has been used by generations of professionals. The new tub has the same tread pattern as the parent Grand Prix 4000 clincher. Its Black Chili tread compound is made with 10x smaller carbon filler particles, so it packs more material into a denser and harder wearing tread compound that is better able to conform to the road surface, therefore offering more grip. A Vectran strip increases puncture resistance compared to Nylon or Kevlar.

I’ve tried many tubulars over many years and it is remarkable how widely they can vary – there are far larger performance differences between tubs than between clinchers. It’s the floating on air sensation that is sought after, with the added bonus of a high pitched “singing” the better quality ones emit. I’m personally more in favour of wider tubs like 25mm as they roll better and corner more confidently. The hairpin bend at Crystal Palace on the Tuesday night crit. is a good test bench for finding out a tyre’s limits.

This two part test began with fitting the tubs to Ambrosio’s Crono rims, the traditional wheel choice of champions like Tom Boonen in harsh Classic events like Paris-Roubaix, Het Volk and the Tour of Flanders, built three-cross for strength and suppleness. Continental tyres and tubs are notorious for coming up a little narrower than other makes, and the 21mm GP4000 tub is no exception.

There is a 25mm version for the same price, which may answer any criticisms. However, 22mm would arguably be a better standard size.

The Ambrosio rims are generous in their width and low in height with a small braking surface. The tub sits in the middle of the well with room to spare either side allowing it to roll slightly while cornering. This has no benefit at all, and in fact allows the tub to squash as it rolls, increasing rolling resistance. Therefore it was concluded that this tub and rim combination is not particularly suited to tight bends or rough conditions. The Contis were swiftly replaced by the fatter 25mm Schwalbes that were on them before.

In the pursuit of light weight and aerodynamic efficiency, and the huge increase in production of carbon components from the Far East, there has been notable resurgence in tubular usage due simply to the fact that most of the modern all-carbon wheel rims will generally only take tubs. The second part of the test entailed fitting the GP4000s to 4ZA carbon deep section race wheels. They sit securely in the well, inspiring confidence while cornering and providing the floaty feeling loved by tub users the world over. Low frontal area creates an excellent aerodynamic profile, it was just me lacking in performance on the sporting 25 where it was put to the test. Optimum pressures to run are 100psi front and 105psi rear (67 kilogram rider) while for 70+ kilograms run at 110 and 115. Do not be tempted to ride tubs too hard on the road just because it says on the label max pressure 170. The vibration and bounce-back you will experience from the rough surface of a road will only slow you down: remember the actual benefit of a pneumatic tyre against a solid one being the absorption of defects in the ground surface.

It strikes me that what makes a good tub is a very round cross sectional shape so that all the benefits of having a tube sewn into a tyre are achieved. The Conti stands a little tall, as do many of their clinchers, making for good longevity at the cost of a little performance, however it certainly rides well as a TT tub and offers resounding reliability. Tubs can be pricey but these are half reasonable at £42.95 each.

Editor’s note: how the tyre is made

Traditional tubular construction comprises a carcass, or ‘pocket’, wrapper around the inner tuber and stitched along the seam. A base tape is stuck over the seam, and a tread stuck to the outer face of the pocket. This technique has served well for a century or more, but has a couple of drawbacks. The seam creates a bulge in the underside of the tub, potentially hindering the sticking process unless the rim be shaped to accommodate the seam. Also, the seam itself is difficult to stitch in a perfectly straight line, so many tubs will run with a slight kink or bulge at some point.

Conti’s new construction technique is closer to that used for a clincher. The fabric of the pocket is laid centrally on a machine in a continuous flat loop. The inner tube is placed over the fabric, and is aligned centrally with the help of laser lines. It is coated with an anti-stick fluid, and the edges are folded over in turn, using the same technology that folds the fabric over a clincher bead, so they overlap by the width of the tyre.

The rubber in the fabric makes the outside surface of one flap adhere to the inside surface of the other, aiding in handling the ‘green’ tub. A strip of rubber is placed on the outside to form the tread, and a fabric band on the inside for the base tape. The whole assembly then goes into a vulcanizing mould, where it is inflated and heated to cure the rubber. The adhered surfaces of the pocket are now vulcanized together, obviating the need for a seam. The tyre takes on the precise dimensions of the inside of the mould, guaranteeing precise alignment and tyre width.

Verdict

21mm format too narrow for crit racing but good TT fitment…

Fast, durable, rolls straight

Fast, durable, rolls straight

Slightly on the narrow side (21mm version)

Slightly on the narrow side (21mm version)