Programmable gears sound like a technology more likely to be found on a Formula One car than the humble bicycle, but it’s a technology at the heart of Shimano’s latest Di2 electronic shifting systems.

Supplementing your toolkit with a laptop will either inspire or terrify you, depending on a readiness to embrace the latest cycling technology, or appreciation for the bicycle as a marvel of simplicity.

Shimano’s system relies on their E-tube, an electronic system that sends two frequencies over a single cable, sending power to a component and controlling how it behaves. Each compatible component (shifter or mech) is fitted with an electronic chip to filter the signal.

The primary function of the E-tube, for road cyclists at least (the same technology is used by Fox for its latest generation of mountain bike suspension systems) is for multiple, continuous gear changes, allowing the rider to shift up or down the cassette several sprockets at a time.

Shimano demonstrated the E-tube and its accompanying software at a press camp in Sicily to launch their R785 hydraulic road disc brake, attended by RCUK<

Shimano’s European product coordinator, Tim Gerrits, said: “Dura-Ace 11-speed, Ultegra 10-speed, Ultegra 11-speed, Alfine – all are based on this platform.”

Riders hoping to program 10-speed Ultegra systems (the 6770 groupset) will need to update their firmware from Shimano’s Project E-Tube website – more of which below.

The components and their electronic chips, what might be called the hardware, are only half the story, however. It is the accompanying software that introduces a programmable aspect to the system. So what exactly can be programmed?

Get with the program

Gerrits was at pains to explain that the function of the lever extends no further than its two switches, which can be programmed variously as up or down (or, if you fancy sabotaging a friend’s machine, only up or only down). The number of speeds in a given system, he said, is a function entirely of the ‘hardware’. A 10-speed rear mech cannot be ‘programmed’ to work across the complete range of an 11-speed cassette, for example.

Shimano are proud of the ‘plug and play’ nature of their E-Tube system, when used with the compatible components mentioned above. Almost all of the components can be connected to each other, allowing time trialists, for example, to set-up satellite shifters on tri-bars. The single exception are Shimano’s ‘sprinter switches’, mounted on the inside of the lever hoods, and which are too small to contain the necessary connector. They are powered instead from the STI lever.

Each system requires one central controller, what Shimano call “junction box A”, typically mounted beneath the handlebar stem, but subsidiary connections, such as those between an STI lever and a time trial shifter, are achieved from “junction box B” – the connection port on every compatible shifter and mech. While any given set-up can only have one junction box A, there is no limit on the number of B connectors.

Project E-Tube

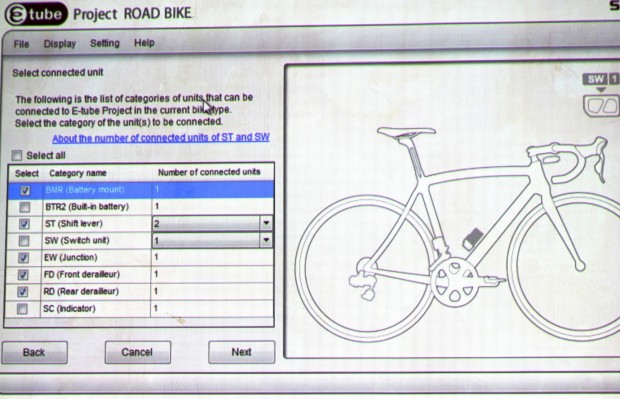

Shimano has launched Project E-Tube, software to support the programmable aspect of their Di2 electronic gear shifting systems, available only for PC platforms, but expected soon in a wireless protocol for Macs. The system allows the firmware of each compatible component to be updated and shifting to be customised. Components with the latest firmware are displayed by the software in green, or in orange for those that require updating.

Multi-shift can be turned on or off via the software, and customised shifting options, including the number and speed of multiple shifts, programmed from it, allowing shifts from a single sprocket to the entire cassette to be achieved with a single push of the button on the STI lever.

Speed settings from “very fast” to “very slow” are available, controlling the intervals between shifts. While the pro cyclists who tested the system initially opted for the former, Gerrits said, the overshifting that resulted convinced many to opt for a slower setting. Typically, the fastest setting is now used only by sprinters, and then only to change down over two or three sprockets to their biggest gear as the prepare for the final few hundred metres of a race, using what Shimano call “burst mode”. The slower settings, conversely, have found favour with climbers, Gerrits continued, whom he said like to ‘feel’ their way into a gear as they establish a rhythm on an ascent.

The latest version of the Project E-Tube software allows individual rider profiles to be saved, and downloaded to the bike, preventing pro team mechanics from having to re-programme a system from scratch for each race.

What’s the diagnosis?

Shimano has a new diagnostic tool, likely to be taken up by independent bike dealers rather than riders. The device attaches to the component and to a laptop. Riders can access the programmable functions of the Project E-Tube software via the charger device supplied with the shifters.