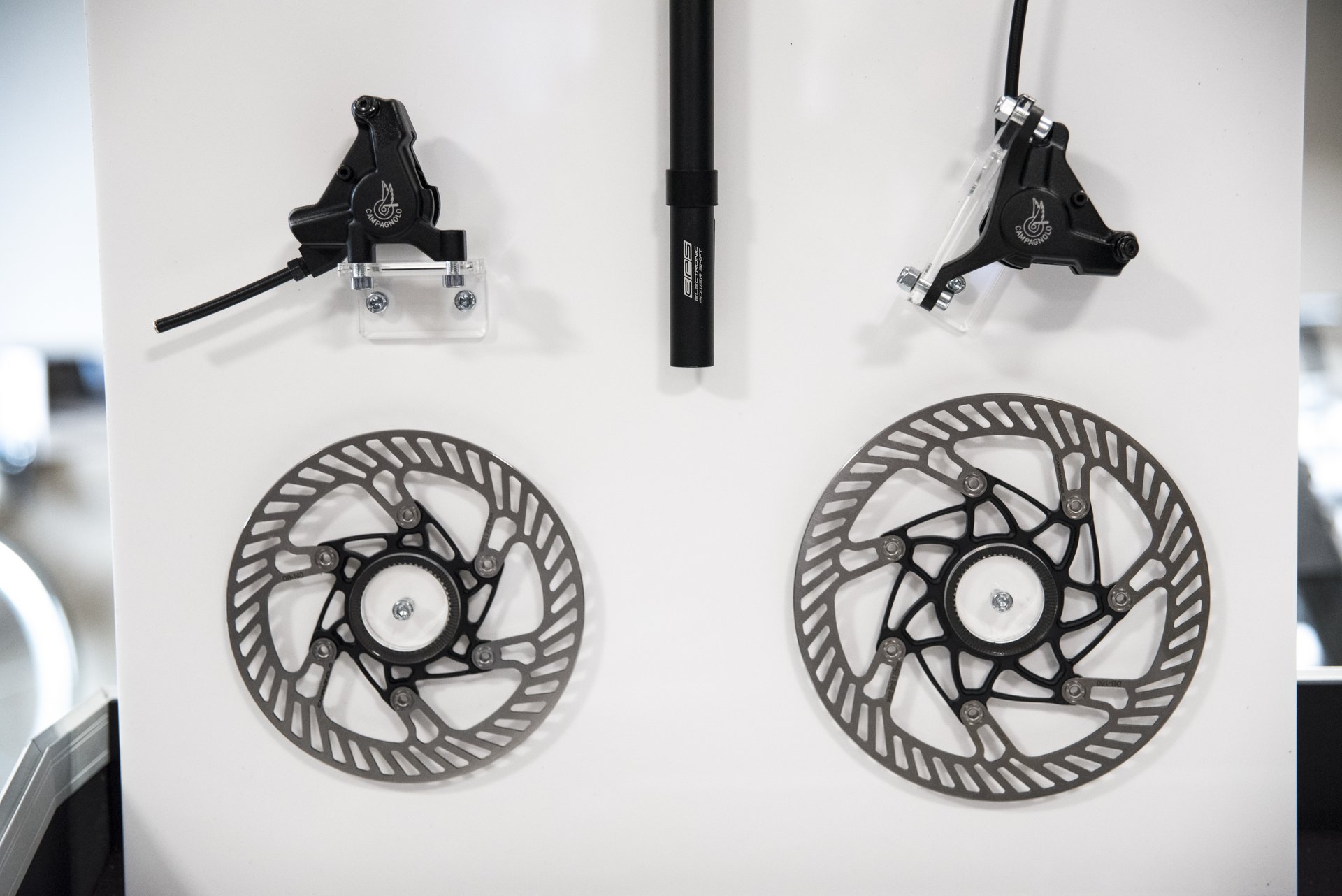

It’s the news we’ve been waiting for. Campagnolo have entered the disc brake market with the launch of hydraulic components compatible with six groupsets, from Super Record EPS right down to Potenza.

In March 2016, Campagnolo invited expectant journalists to Gran Canaria to see what was new from the Italian firm. We expected disc brakes but got the mid-range Potenza groupset and only a sneak peek at Campag’s prototype discs. This time, however, we weren’t to be disappointed and Campagnolo have finally joined Shimano and SRAM in offering road disc brakes.

– Campagnolo unveil entry-level Centaur 11-speed groupset –

In fact, Campagnolo reckon their disc brakes decelerate 23 to 26 per cent quicker in wet conditions, depending on the competition, and between 14 and a huge 55 per cent in dry conditions. We can’t verify those claims, but it gives an indication of what Campagnolo are trying to achieve.